products center

Contact info

Evaporative Cooled Condenser Packaged Water Chiller

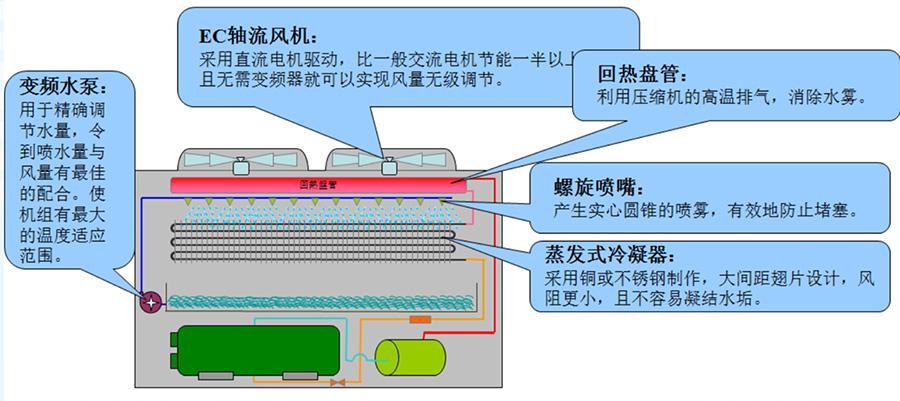

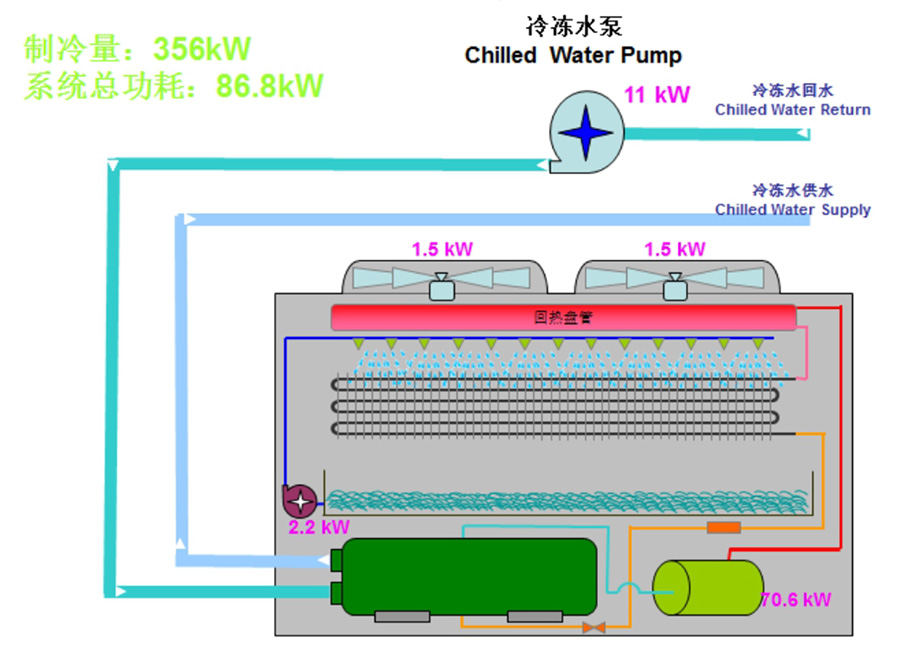

Schematic diagram and working principle of evaporative cooling technology:

1. The evaporative cooler uses water and air as the cooling medium, and uses the evaporation of water to take away the cooling heat of the vapor refrigerant. In general, the temperature difference between the inlet and outlet of the water-cooled condenser is 4~6℃. Theoretically, in a water-cooled condenser, 1kg of cooling water can take away 16.72~25.08kJ of heat, while 1kg of water has a latent heat of vaporization of 2418kJ at 35°C under normal pressure, and the heat exchange efficiency is greatly improved. At the same time, it eliminates the sensible heat transfer stage of the cooling water in the condenser, so that the condensing temperature may be closer to the wet bulb temperature of the air. Its condensing temperature is 4~6℃ lower than that of the cooling tower water-cooled condenser system, which is higher than that of the air-cooled condenser. The condenser is 10~14℃ lower, which greatly reduces the power consumption of the compressor.

2. When working, the cooling water is pumped to the nozzles on the upper part of the cooling tube group and sprayed evenly on the outer surface of the cooling tube to form a very thin water film. The high-temperature vapor refrigerant enters from the upper part of the cooling tube group and is The cooling water outside the tube absorbs heat and cools into liquid and flows out from the lower part. Part of the heat-absorbing water evaporates into steam, and the rest falls in the lower catchment tray. The water supply pump is used in circulation, and the fan forces the air to cool at a speed of 3m/s. The exhaust pipe promotes the evaporation of the water film, strengthens the heat release outside the cooling pipe, and makes the absorbed water droplets be cooled by the air during the falling process. The evaporated water vapor is discharged by the fan with the air, and the unevaporated water droplets are blocked by the dehydrator. Back to the water tray.

Features

Integrated design: Built-in cooling water pump, heat exchanger through special treatment, so that the heat exchanger will have a life extension effect under the condition of frequent contact with cooling water. Equipped with an imported water system descaler, the life of the whole machine will be escorted.

Natural cooling function: In winter and spring and autumn nights, when the ambient temperature reaches 10 degrees or more lower than the return water temperature of God and East Water, FREECOOLING natural cooling chilled water, no compressor power consumption part, only a small amount of fan power consumption .

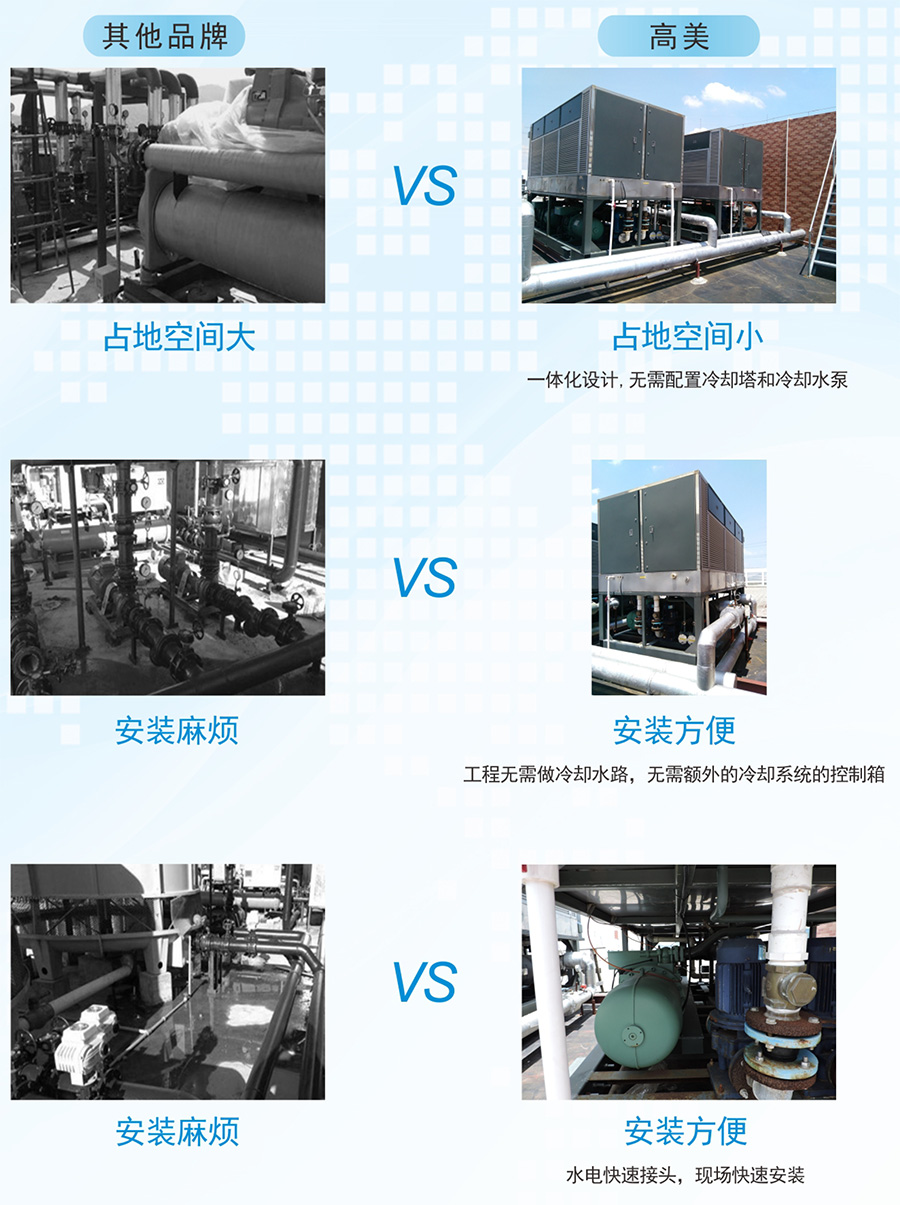

Less space occupied: The equipment is light and handy, no cooling tower and cooling water pump are required, no cooling water circuit is required for the project, and no additional cooling system control box is required.

Fast installation: Quick connection for water and electricity, quick installation on site.

Energy saving and power saving by 30%: The energy efficiency ratio of air conditioning units is 4.5, and the integrated partial load efficiency IPLV reaches 8.2 or more. Under standard working conditions, the whole machine has a high energy efficiency ratio, which is more than 15% energy-saving than traditional water-cooled chillers, and 30% more energy than ordinary air-cooled chillers. The energy efficiency ratio exceeds international energy efficiency standards.

Advantages: high anti-corrosion performance, high unit stability; compact structure, reasonable layout; equipped with a descaling device to prevent fouling; advanced logic control, fuzzy logic, precise control of load changes, and more stable operation.

Scope of application:

For civil use: use thousands of large shopping malls / hotels / hotels / government buildings / stadiums / cinemas / hospitals / high-rise buildings / entertainment centers, etc.

Industrial: precision computer room/data center/food/electronics/chemical/machinery/textile and other factories.

The company's evaporative condenser units are very advantageous in terms of installation cost, installation space, use cost, and maintenance cost, and the prospects are optimistic. It is suitable for all kinds of industrial and commercial air conditioning or process chilled water preparation, especially suitable for air conditioning or process occasions in low wet bulb temperature areas and year-round refrigeration.

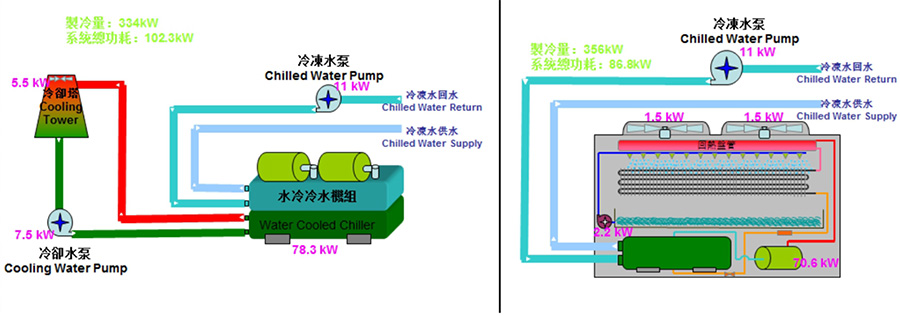

Comprehensive comparison of high-efficiency evaporative chillers

Comparison of evaporative chillers, air-cooled chillers, and water-cooled chillers:

Comparison of evaporative condenser water system and traditional radiator + cooling tower water system

The performance of the same compressor under two systems

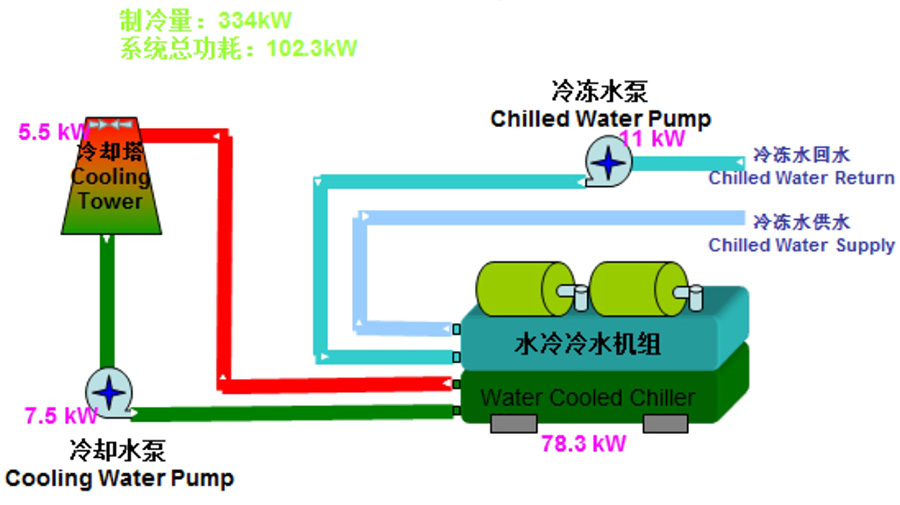

Water-cooled chiller + cooling tower

·High condensing temperature brings higher compressor power consumption.

·The refrigerant needs to exchange heat with water, and then use hot water to exchange heat with air. The heat exchange rate is low and the condensation temperature is high.

·The water pump needs to overcome the resistance of the pipe lift and consumes a lot of power.

·The water system piping is complicated, and the equipment installation works are large.

Evaporative chiller

·The refrigerant can directly exchange heat with air and water through the copper tube, with high heat exchange efficiency and low condensation temperature.

·Low condensing temperature, compressor power consumption is smaller.

·The pump has low resistance and low power consumption.

·The pipeline of the water system is simple, and the amount of equipment installation is small.

·The heat dissipation air volume is smaller than the cooling tower, and the fan power is low

Technical parameters of high-efficiency evaporative chillers

Evaporative condensation technology:

1. Under standard operating conditions, the whole machine has a high energy efficiency ratio, which is more than 15% energy-saving than the traditional 7-cooled chiller, and more than 30% energy-saving than the general air-cooled chiller. The energy efficiency ratio exceeds the international first-class energy efficiency standard.

2. The system does not need to be equipped with a cooling water tower and a high-power cooling water pump, the installation is simple, and the project investment cost is reduced. The amount of cooling water used is small, which completely eliminates the phenomenon of water flying in the cooling water tower. Compared with the water-cooled chiller using the cooling water tower, it can save more than 50% of the water. A variable frequency spray water pump is used to adjust the spray volume according to the system pressure of the evaporative unit to achieve energy-saving effects.

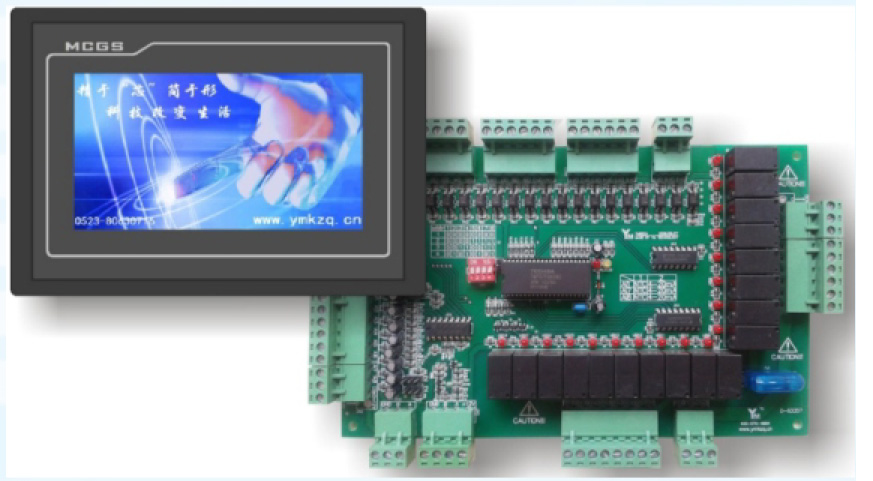

Simple control interface, easy operation and maintenance

1. The control interface adopts LCD touch screen display, unit operating parameters, menu management, so that the unit operating parameters are clear at a glance, and the operation is simple and convenient.

2. On the control interface, you can easily see the inlet/outlet water temperature, inlet air temperature, cooling water temperature, system high and low pressure values on the unit.

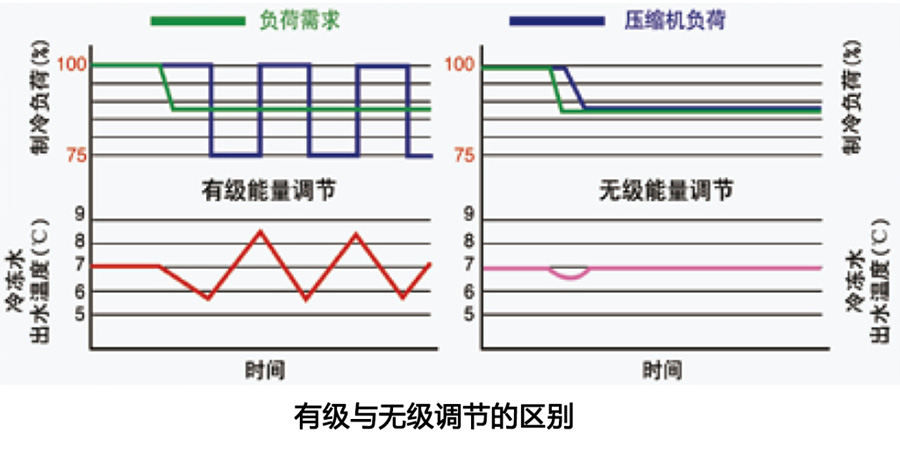

Stepless adjustment, high comfort

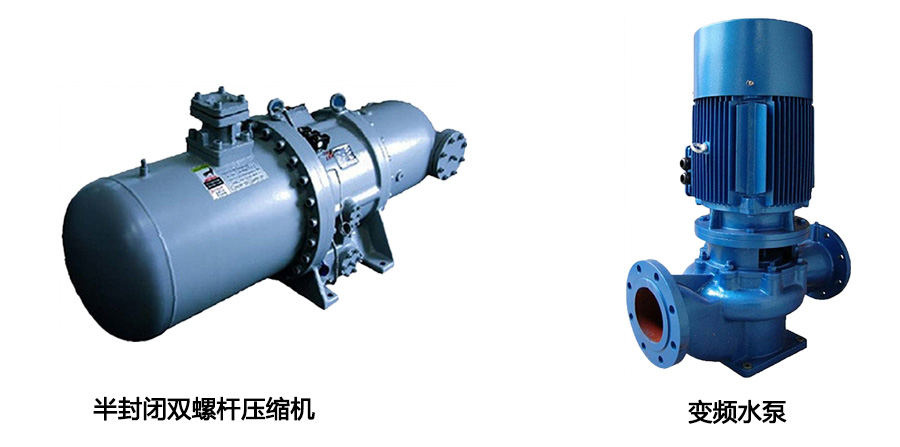

1. The unit adopts twin-screw compressor, which can be steplessly adjusted from 25% to 100% load.

2. Ensure that the outlet water temperature is stable, the output capacity of the unit is fully matched with the load required by the building system, and the energy is "output on demand", and the unit is maintained under partial load.

3. Energy and water temperature adjustment make users feel more comfortable. Fuzzy control is used to predict and compensate air-conditioning load changes according to the temperature and change rate of chilled water, making load adjustment faster and more stable.

High-precision control, reliable operation

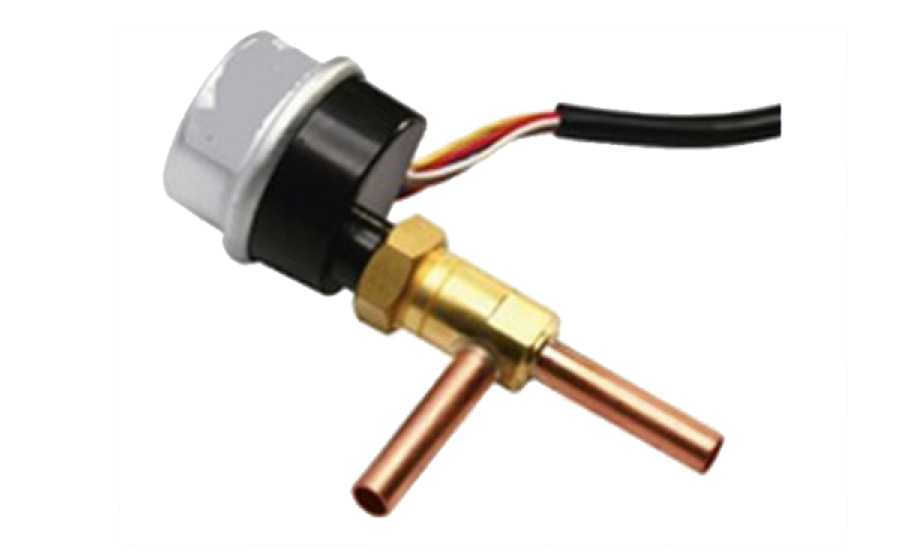

1. The evaporative chiller is equipped with an international famous brand electronic expansion valve, which can accurately control the refrigerant flow, so that the unit can adapt to a variety of working conditions and actual multiple control functions.

2. The various sensors of the system can accurately transmit the signal data to the controller, so that the controller can protect the unit components in time and make the unit operation more reliable.

3. The compressor starts at low load, and the starting current is small, reducing the impact on the power grid.

Equipped with imported descaler

The water system of the evaporative chiller is equipped with a descaler imported from abroad. This descaler has been verified by an authoritative testing center and the quality is guaranteed. The electronic descaler uses a high-frequency magnetic field to change the physical structure of the water flowing through, change the state of sediment in the water, and make it difficult for scale to form, and at the same time, it will melt the original scale.

Intelligent control, reliable

1. The electronic control components and microcomputers of international famous brands can only be controlled by the controller, with advanced control, complete functions and high degree of automation, which can realize the mechanism start-stop program management, timing control, full-function fault alarm and fault self-diagnosis functions.

2. The controller has perfect self-control function and super anti-interference ability, and has multiple protections such as lack of phase, phase sequence, three-phase imbalance, compressor overload, fan overload, abnormal suction and exhaust pressure, and anti-freezing protection to ensure The operation of the unit is reliable.

long lasting

The heat exchanger is sprayed to protect the corrosion resistance of the heat exchanger without affecting the heat exchange effect. The stainless steel structure is used in the spray system to reduce corrosion to the unit.

Enquiry:

Product information

- Product serial number

- Thumbnail

- Name of product

- Product serial number:

-

- Evaporative Cooled Condenser Packaged Water Chiller

Contact information

Related Cases:

Related Documents:

Copyright

©

2021

Guangdong Cold Magic Air-Conditioning Equipment Co., Ltd.

IPv6